This can cause the hole to deform the edge or the other hole. Disc springs have become indispensable in a host of applications.

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Capacity to store potential mechanical energy.

. Compression Spring Constant k Calculator Compression Spring Calculator This calculator will calculate any of the values remaining by changing one of the variables then selecting the calculate. Ad Browse discover thousands of brands. For static applications guides can be unhardened.

6Largely Self-damping giving good shock absorption and energy dissipation. The characteristics will be changed and even fatigue cracks can occur. Advantages of Disc Springs.

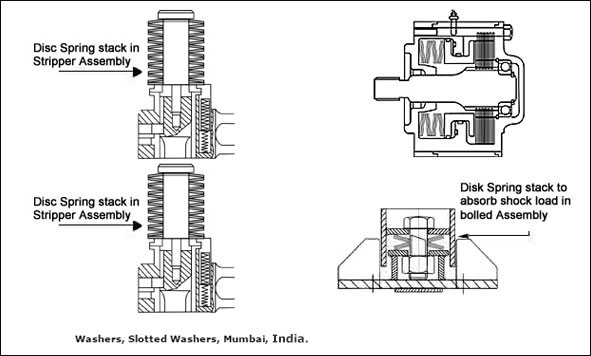

If a component requires bends perpendicular to each other with radii close the minimum bend radius it is good design practice to orientate the component by 45º relative to the rolling direction. The active wire length La can also be used to form an expression for the deflection. Because Belleville washers can bear a much larger load relative to its deflection rate than a coiled spring they are ideal for cushioning heavy loads with short motion.

And the preload is 15 of the initial height of the spring while the final position is 75 of its initial height. 4Stock keeping is minimized as the individual spring sizes can be combined universally. Disc springs are also called Belleville spring washers and conical spring washers.

The outlined above can be used to estimate the fatigue life of a disc spring. Power transmission components such as clutches brakes transmissions Valves piping and drilling tools. Button for the selected variable.

Disc springs can used as single or multiple units. This spring rate is usually very high allowing the spring to produce very large loads in a very small space. Stainless steel disc springs can be filtered by outside diameter inner diameter thickness reduced thickness as well as othe specifications.

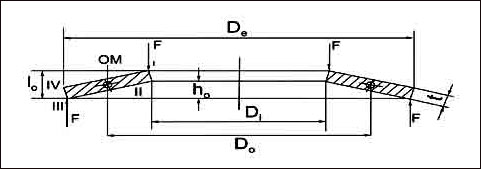

The disc springs have flat annular grooves cut in the inner and outer diameter. A Belleville spring is a conical shaped disc that will deflect flatten at a given rate. A disc spring is a spring washer with a conical shape.

Aternatively you can download our Disc Spring PDF stock list below. Read customer reviews find best sellers. This shape gives the spring washer its flexible effect.

Ball bearing centering is typically used on large disc spring stacks. Disc Springs Applications are. The hardened ball bearings are inserted in these grooves.

Above ratio 15 the disc spring will adopt a regressive characteristic and is capable of push-thro if not fully supported. Wire-centered disc spring stacks. A Belleville washer or disc spring is a conical-shaped spring with an open center.

Free shipping on qualified orders. Applications requiring a high degree of safety are also reliably. The guide elements and abutments should be hardened if possible to a minimum of 60 HRC minimum case depth of 08 mm.

Disc Spring Materials Standard Range Specialised Applications Protective Surface Treatments. These springs are manufactured from Ck 67 and 50 CrV 4 and are typically available from stock. This type of guidance is virtually friction free.

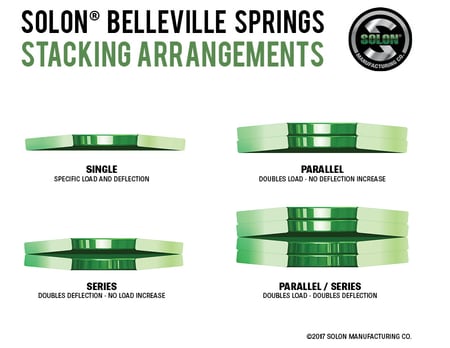

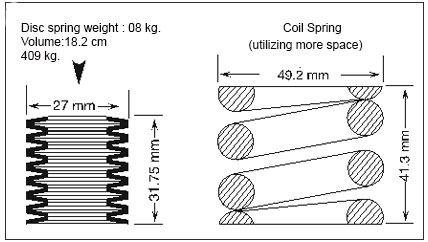

When stacked in multiple units they can be stacked in series to give a low stiffness value or in parallel to give a higher stiffness value. Guide The surface of guide elements is dynamic disc spring applications always has to be harder than the disc springs themselves. Disc springs are also capable of providing more force in less space than a compression spring or wave spring.

The surface of the guide element should be smooth and if possible ground. The standard corrosion protection is zinc phosphating and oiling. 2High Energy Storage Capacity.

1No Deformation or Fatigue under normal loads. Tel 818 767-1886 Fax 818. Disc Springs are conically-shaped washer-type components designed to be axially loaded.

Relatively small spring travel. FAN DISC CORPORATION 8127 Clybourn Avenue Sun Valley CA 91352. Avoid punched holes or slots too close to the edge of the component or another hole.

Application is a new design or a maintenance requirement Daemars global partnerships offer you one of the most complete sources of supply for Disc Springs. The properties of the disc spring make it unique in applications where space is limited - but where high force is wanted. Free easy returns on millions of items.

This again causes uneven movement during the deflection of the spring. Screwed or bolted sections. Stainless steel disc springs X12CrNi 17 7 DIN 14568 are available with an outside diameter of 355mm to 1120mm.

For instance if such a spring has an inside diameter outside diameter and thickness of 254 millimeters 50 millimeters and 2 millimeters respectively. Single one spring Parallel all springs stacked the same way. A disc spring is a conical shell spring which is loaded along its axis.

For more technical information concerning disc springs we ask you to use our technical handbook. Disc springs to Factory Standards or other as required Size range. This spring design principle corresponds to the disc spring in use today.

Belleville springs can be stacked in a variety of ways. Disc springs with cone heightthickness ratios above 20 may invert when compressed toward the flat condition. What makes Disc Springs unique is that based on the standardized calculations of DIN EN 16984 formerly DIN 2092 the deflection for a given load is predictable and the.

It is shaped much like a washer and is typically smaller than a coiled spring. The use of disc springs is common in applications requiring high spring forces and small deflections. The Standard Product Range of disc springs sizes to DIN 2093 and Factory Standards includes 246 sizes with outside diameters between 8 and 250 mm.

Outside diameter 60 mm to 800 mm Materials to DIN 2093 DIN 17 221 DIN 17 222 and special. A minimum of 55 HRC is advisable otherwise 8 the surfaces can be damaged. This again causes uneven movement during the de fl ec - tion of the spring.

The conical design of spirol disc springs makes their spring characteristics and performance more predictable than traditional compression springs. Home Spring Selection Special Springs Spring DESIGN About Request Quote. The wire diameter d should conform to a standard size if at all possible.

The spring index C can be used to express the deflection The useful range for C is about 4 to 12 with an optimum value of approximately 9. They are commonly stacked. A minimum of 55 HRC is advisable otherwise the surfaces can be damaged.

Guide The surface of guide elements in dynamic disc spring applications always has to be harder than the disc springs themselves. Proper guidance and location of disc springs is essential to their performance and will ensure that the desired characteristics and repeatability is achievedrecommended guide clearances are shown in the tolerance tables and it is also necessary to pay some attention to the nature of the guidance and seating surfacesmuch depends upon the.

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Belleville Spring An Overview Sciencedirect Topics

Belleville Spring Technical Notes Disc Spring Tech Notes

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

0 comments

Post a Comment